How Technology is Transforming Health & Safety Compliance

Managing health and safety compliance has become increasingly complex, with organizations facing challenges in risk identification, reporting accuracy, and contractor safety management. Many businesses still rely on manual processes, which can lead to delays in hazard detection, inefficient audits, and compliance gaps.

Technology, especially AI, predictive scoring, and real-time analytics is changing the way organizations manage health and safety. These tools allow safety and procurement teams to move from reactive reporting to proactive risk management, while maintaining full audit readiness.

Why Digital Transformation Matters in Safety Compliance

According to Protex AI, businesses that implement AI-driven safety analytics experience a 50% reduction in reportable workplace incidents.

A study by the University of South Florida College of Public Health found that AI-powered occupational safety monitoring can detect up to 95% of workplace hazards in real time. This allows companies to act on risks before incidents occur.

Additionally, research from the CDC’s National Institute for Occupational Safety and Health (NIOSH) highlights that automated compliance tracking improves audit efficiency and accuracy. This helps businesses meet evolving regulatory requirements

This article explores five key ways technology enhances health and safety compliance, making workplaces safer and reducing administrative burdens.

1: Real-Time Compliance Tracking for Proactive Safety Management

For organizations operating across multiple sites and contractors, keeping track of safety certifications, regulatory requirements, and audit readiness can be a challenge. This is especially true especially when it’s managed through spreadsheets, email reminders, or siloed systems.

Real-time compliance tracking centralises and automates this process. It ensures that supplier credentials, health and safety documents, and audit statuses are always up to date. When issues arise — such as a lapse in training certification or a failure to meet a site-specific safety policy — the system flags it immediately. This enables procurement, health and safety, and project managers to intervene quickly, reducing downtime and preventing compliance breaches before they escalate

How Real-Time Tracking Strengthens Workplace Safety

- Instant access to compliance data – A centralized system allows organizations to see which suppliers, contractors, and employees are meeting health and safety requirements

- Automated alerts for non-compliance – Instead of waiting for an audit, businesses can receive notifications when safety certifications expire or when a contractor fails to meet specific requirements.

- Better visibility across the supply chain – With compliance tracking tools, companies can proactively assess supplier safety performance, ensuring alignment with HSEQ standards.

- Audit-ready documentation – Reduce time spent on manual tracking by automatically updating compliance records, making audits more efficient.

- Regulatory alignment – Digital tools ensure businesses stay compliant with HSEQ standards, reducing the risk of fines or legal issues.

By integrating real-time compliance tracking into daily safety operations, businesses can take a more proactive approach to managing risk, ensuring that safety remains a priority at every level.

Further Reading: Understanding Supplier Safety Compliance and Risk Management

2: Digital Risk Management for Smarter Safety Decision-Making

A reactive approach to risk management increases the likelihood of incidents, legal exposure, and supply chain disruption. Without a centralised view of contractor performance and incident trends, it’s difficult to prioritise which risks need urgent attention and where to allocate limited resources.

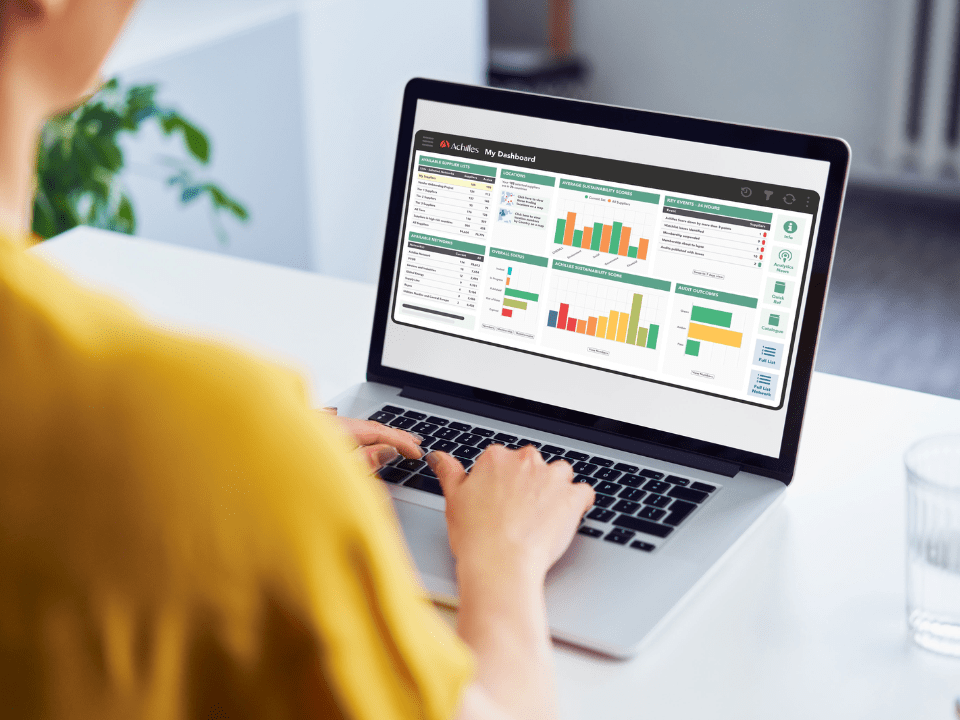

Digital risk management tools, like those within the Achilles Platform, enable smarter, data-driven decision-making. By combining structured supplier data with predictive scoring and analytics, organisations can assess safety risk at a glance and prioritise your business strategic vulnerabilities.

How Digital Risk Management Enhances Safety Oversight

- Risk-Based Supplier and Contractor Evaluations – Businesses can assess suppliers and contractors based on historical safety performance, ensuring they work with the safest partners.

- Data-Driven Safety Trend Analysis – Digital tools help organizations analyze trends in safety incidents, near misses, and audit results, making it easier to spot patterns and intervene early.

- Proactive Hazard Identification – Rather than waiting for an incident to trigger an investigation, digital platforms help businesses flag potential risks in advance based on historical data and compliance scores.

- Resource Allocation for Maximum Impact – Businesses can use risk scores and compliance insights to determine which areas of their operations require more attention, instead of applying a one-size-fits-all safety strategy.

- Automated Reporting for Efficiency – Instead of compiling safety data manually, digital platforms centralize information, reducing the administrative burden of risk management.

A reactive approach to workplace safety increases costs, legal risks, and operational disruptions. By using digital risk management tools, businesses can move beyond compliance tracking and develop a smarter, more predictive approach to safety oversight.

3: Digital Reporting & Audit Readiness for Streamlined Compliance

As health and safety regulations evolve, businesses that rely on manual audits and fragmented reporting risk non-compliance and inefficiencies. Digital reporting tools automate, structure, and prepare compliance processes for audits.

Reporting platform such as Achilles Analytics brings compliance data to life. They transform risk-related information from supplier pre-qualification, audits, and incident tracking into configurable dashboards that can be analysed at company, project, or regional level.

How Digital Reporting Improves Compliance Management

- Live dashboards highlight risk indicators across your entire contractor base, with filtering by geography, business entity, or category

- Audit trail functionality ensures that all documentation is versioned, timestamped, and accessible for inspection at any time.

- KPI visualisation allows users to track trends over time, such as reductions in non-conformances or improvements in safety training coverage.

- Faster Incident Investigations – Digital tools enable organizations to search, retrieve, and analyze historical data instantly. This improves the efficiency of incident reviews and root cause analysis.

4: Enhancing Contractor Safety Management through Supplier Pre-Qualification

Your contractor network is only as strong as your weakest supplier. Without a structured approach to evaluating and monitoring contractors, organizations may face increased risks due to non-compliance with safety standards.

Supplier pre-qualification serves as a proactive measure to assess and verify the safety credentials of contractors before engagement, ensuring they meet the necessary health and safety requirements.

How Supplier Pre-Qualification Improves Contractor Safety Management

- Thorough Evaluation of Safety Practices: Pre-qualification involves assessing contractors’ health and safety policies, procedures, and performance records, ensuring alignment with organizational standards.

- Consistent Compliance Monitoring: By maintaining up-to-date records of contractors’ certifications and compliance statuses, organizations can ensure ongoing adherence to safety regulations.

- Risk Mitigation: Identifying potential safety risks associated with contractors before engagement allows for informed decision-making and the implementation of necessary controls.

- Efficient Selection Process: A standardized pre-qualification system streamlines the contractor selection process, saving time and resources while maintaining safety standards.

5: AI & Predictive Insights for Risk Management

Advancements in artificial intelligence (AI) and the Internet of Things (IoT) are transforming risk, esg and health and safety compliance by providing real-time data collection, predictive insights, and automated risk detection.

By analysing structured data from across the supply chain, including policy compliance, audit outcomes, and incident trends AI and predictive models can surface early signals of risk. This supports earlier and more informed decision-making.

How AI & Predictive Insights Improve Health & Safety Compliance

Through platforms like Achilles, organisations can access configurable dashboards and performance indicators that support:

- Pattern recognition across supplier types, locations, or project phases

- Resource prioritisation based on real-world risk indicators

- Forward-looking views of risk, rather than lagging compliance alone.

How Technology Strengthens Risk and Health & Safety Compliance

Ensuring risk and health and safety compliance is no longer just about meeting regulatory requirements. It is also about understanding where risk lives in your supply chain and using that insight to create continuous improvement inline with business goals.

A data-informed approach supports regulatory compliance as well as empowering smarter decisions, more efficient resource allocation, and a stronger safety culture across the value chain.

In a landscape where scrutiny is growing and expectations are rising, digital transformation isn’t optional, it’s the foundation of modern health and safety strategy and supply chain risk management.