The world of transport and logistics is in the midst of a transformation

As the sector seeks to support carbon emissions goals by moving to greener technologies major infrastructure investment is required over the coming decades. This includes EV charging, resilience to climate change, intelligent transportation systems, autonomous vehicle infrastructure, renewable energy integration and mobility-as-a-service (MaaS).

A global change

The transport sector is not alone. Overall, total annual energy-related investment is expected to surge to USD 5 trillion by 2030. This will add an extra 0.4 percentage points a year to the annual global GDP growth. This will lead to creating unprecedented competition for much needed raw materials, expertise, sub-contractors and suppliers. This increasing demand is having environmental and social implications. There are instances of forced labour linked to solar panel manufacturing, Amazon deforestation linked to wind turbine manufacturing and marine and fish stock damage in Indonesia from illegal nickel mining.

As this shift continues, transport leaders are becoming increasingly aware that the changing transport supply chain is becoming more time-critical and resource-intensive. This inevitably leads to a growing in complexity that is prone to compliance risks. They are not alone. In fact, in a recent Unseen survey on LinkedIn, 42% of respondents said that the supply chain was the biggest challenge when it comes to addressing modern slavery risks. This is one of the biggest compliance issues facing organisations. As in many sectors, transport organisations are struggling. It is difficult to find the resources to deliver the new levels of supply chain risk management that is now required.

A supply chain regulatory net

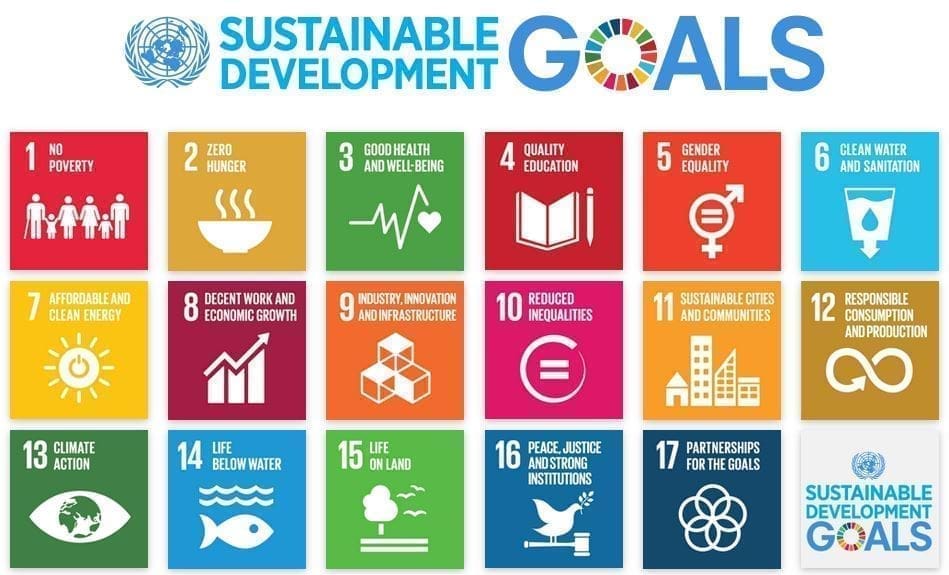

The UN’s 17 Sustainable Development Goals aim to tackle climate change, human rights abuses and environmental degradation.

Regulation is coming into force to support those goals requiring greater supply chain focus. From Canada’s Bill S-211 to the EU’s CSDDD and India’s BRSR Core. In addition, the rise of “green finance” is creating further impetus for a stronger ESG focus and more supply chain transparency. This is to support the level of transport-related investment that is required.

Technology: The obvious solution?

The obvious solution is to turn to technology, but what is the best approach? Many transport leaders may believe that their procurement and supply chain management processes are already as transparent and optimised as they can be. The reality is often a web of spreadsheets, old-fashioned forms, and manual data entry processes. Even to maintain supply chain management and reporting at current levels there are bound to be significant gaps.

Often, the reality is that these error-prone, costly, time-consuming systems and processes are anything but efficient and fail to deliver the level of reporting confidence that is increasing required.

Truly efficient transport supply chains

Truly efficient and robust end to end supply chain management must include:

- Data capture from multiple sources, in different languages and formats

- Meticulous data checking and verification

- Comprehensive risk assessment

- Demonstrable risk mitigation

- Real-time access to data and reporting

- Supplier performance statistics

- Integrated new supplier onboarding process

Utilisation of an ERP and spreadsheets does remove some manual effort. Due to complexities it is becoming harder and harder to meet business and compliance requirements in this way. The ongoing maintenance of running manual processes and spreadsheets leads to high total cost of ownership (TCO). Much of that is below the surface as an opportunity cost, so it’s never fully accounted for. What most procurement teams recognise it as a massive burden and a distraction from higher value activities

So what is the alternative?

More and more companies are shifting away from managing suppliers within their ERP and spreadsheets. Instead, they are looking for specialized solutions where data can be managed, analysed and reported in a controlled but flexible environment. Data can then be shared with the ERP for general business and procurement needs.

In the UK, the Link-Up network enables rail and other transportation providers to share the burden of supplier qualification, supply chain due diligence and reporting. Major buyers share access to a pool of pre-qualified and regularly audited suppliers across a wide range of product and service categories. This makes procurement and supply chain reporting more streamlined and cost-efficient.

A similar approach is used in Norway with the the TransQ network. This network supports transport supply chain management and compliance with Apenhetsloven, the Norwegian Supply Chain Transparency Act.

When should you consider a third-party supply chain due diligence solution?

While some ERP solutions offer supply chain management, they are usually just one small piece in an ERP’s broad array of solutions. This means that developing and updating them to keep up with changing supply chain legislation and stakeholder reporting requirements may not be a major area of focus or investment for the vendor. They won’t include the data collection, validation and analysis that is central to the new wave of supply chain legislation

Simple spreadsheets may be a good fit for some businesses. These tend to be the organisations with less complex supply chains, lower levels of stakeholder scrutiny and fewer reporting requirements. When managing major complex transport projects, these types of solutions are unlikely to provide the data validation, due diligence or risk analysis required. They are also likely to increase the need for manual workarounds and carry the risk of failing to meet increasingly stringent reporting requirements.

If a business opts for an in-house developed solution, it can be difficult to maintain as supply chain obligations evolve. The constant development often becomes an unwelcome distraction for an IT team that wants and needs to be focused on the core business. Businesses often find, what starts out looking like a cost-effective solution quickly starts to incur unforeseen management costs. Generally this is due to updating and maintaining systems, or a need to hire additional headcount to handle the required manual efforts.

What about the supplier burden?

With all these in-house solutions, you will also be placing increased pressure on your suppliers. They will have to fill out your forms and comply with your processes. Not only this, but also the forms of all the other businesses they supply. Solutions that enable industries to work collaboratively to identify risk and improve overall supply chain performance, provide efficiencies for buying organisations. They also have the additional benefit of reducing the burden on the suppliers themselves.

How to choose the right supply chain due diligence solution for you?

As you evaluate your current supply chain due diligence processes, you should consider three key areas that can greatly impact your organisation, now and in the future:

- Complexity: How complex or fragmented is your supply chain? Do your suppliers stretch across countries and continents? Do you buy from countries where language is a barrier to communication. How up to date is your supplier contact information and how good is your supplier engagement really?

- Risk level: In transport, health and safety is always a key concern. Major infrastructure projects often involve layers of sub-contractors making it challenging to maintain standards. It can also be hard to find suppliers with the credentials to meet your requirements and project timescales. How much do you source from markets where environmental and social standards may be an issue.

- Reporting requirements: What sort of reports do you need to produce to meet stakeholder, investor, and regulatory requirements? How will you keep track of regulatory changes? How does the solution handle ongoing changes and modifications. Are manual interventions required?

| Small business to mid-market supply chain management | Mid-market to multi-national supply chain management |

| Minimal supply chain complexity | Complex supply chains |

| Small businesses to mid-market | Mid-market to multi-national corporations |

| Low risk operations | High risk operations |

| Less regulation | Increasing regulation |

| Lower number of reporting requirements | Higher number of reporting requirements |

| Low public scrutiny | Increasing public interest |

| Low reputation impact | High reputational impact |

AI and web scraping isn’t always the best option

It can be tempting to rely on lower-cost AI generated or web-scraped information. This problem with this is that instances of forced labour, child labour, and environmental pollution are rarely found on the internet. That is until they become the subject of a media exposé. If you are working internationally and are exposed to increasing legislation, only by using local knowledge and connections, working closely with NGOs and undertaking site audits and worker interviews in the highest risk locations will you ever hope to get close to the level of understanding you need.

Taking the next steps

The supply chain processes of transport organisations has a high focus on health and safety and other sustainability concerns. This means they operate in highly regulated environments. A supply chain that spans international borders is inevitably complex. This leads to a need for better data, greater analysis and more automation and compliance. If you’re ready to consider the benefits of a professional supply chain management solution, consult the ratings and reviews of the available options on the market or talk to one of our experts today.